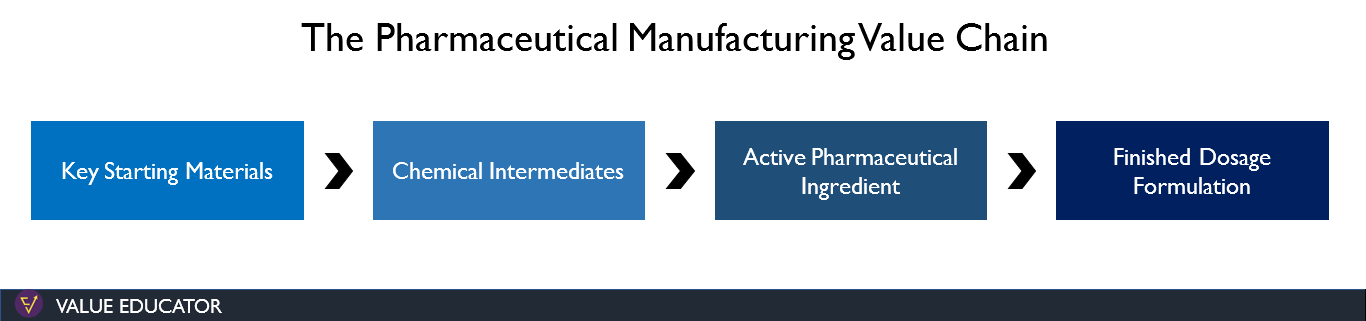

There are hundreds of pharmaceutical businesses listed on the stock exchanges. These companies perform different activities pertaining to pharmaceuticals. Some companies are involved in the manufacturing of pharmaceuticals whereas others are involved in sales and distribution of pharmaceuticals. Within these sections there are companies that perform different functions that are integral to getting a finished product that is consistent in quality and safe for consumption. Many companies perform all these functions and are present across the value chain, whereas some companies choose to focus on one specific area.

When trying to understand what function a company performs specifically, we come across various terms that make it difficult to understand where a pharma company lies specifically in this value chain and what are the advantages or disadvantages of occupying that niche. We have attempted to simplify the building blocks of the manufacturing of pharmaceuticals to give a basic understanding of the pharma value chain.

Key Starting Materials

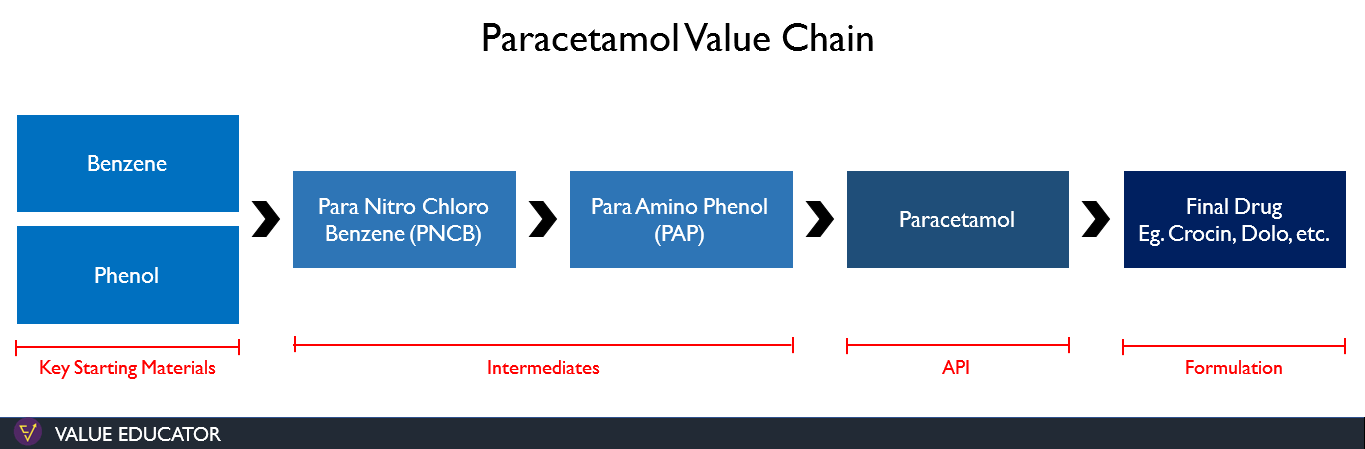

Most medicines begin their journey as basic chemicals. These basic chemicals form the building blocks that go through various multi-step reactions to become the final drug that we consume. These key starting materials can be derivatives of crude like benzene or phenols, or they can be chemicals derived from natural sources like statins (cholesterol reducing drugs) which are produced from fungi. These products are usually high volume and low margin in nature and are essentially commodities that are subject to price volatility due to various demand and supply factors.

Chemical Intermediates

Intermediates are derived through various reactions of KSMs. These intermediates are manufactured through single or multiple step processes for specific applications like pharmaceuticals or agrochemicals. Intermediates act as raw materials for manufacturing bulk drugs/APIs by themselves or in combination with other intermediates.

Active Pharmaceutical Ingredients

Active Pharmaceutical Ingredients (API) are the main component of a medicine that has the intended therapeutic effect on the body. APIs are manufactured through multi-step processes by purifying various intermediates. API makes up only a small portion of the final drug but is the most important part of the drug. You can find out how much API is contained in the final drug from the package of the drug. In a nutshell, basic chemicals go through various chemical reactions and are purified until they reach a very high level of purity to finally become an API. Today, a majority of APIs in India are imported from China.

Finished Dosage Formulations

Finished Dosage Formulation (FDF) is the final drug that is consumed by the patient. To make a finished formulation, the API is mixed with various excipients (inactive ingredients). Excipients can be a variety of things like bulking agents, stabilizing agents, flavoring agents, dyes, etc. These excipients act as carriers for the active ingredient which is going to have the therapeutic effect on the body. FDFs can take various forms like tablets, capsules, syrups, solutions, etc. which are then packaged and marketed to consumers.

Now that we know the basic terminology behind the manufacturing process, let us look at an example to understand the value chain a little better. We have taken the example of Paracetamol – which is one of the most common drugs in the world.