Rally in Sugar stocks

- In recent times, sugar stocks have given more than 50% returns to its investors in the period of 6 months. The sole reason behind this rally is the word “ethanol”

- Sugar companies manufacture ethanol which has application as industrial solvent and most importantly used in blended fuel.

- Ethanol is the recent buzz word due the initiative of E20 roadmap by the government of India and expansion of capacities by Indian sugar companies.

Need for Ethanol in India

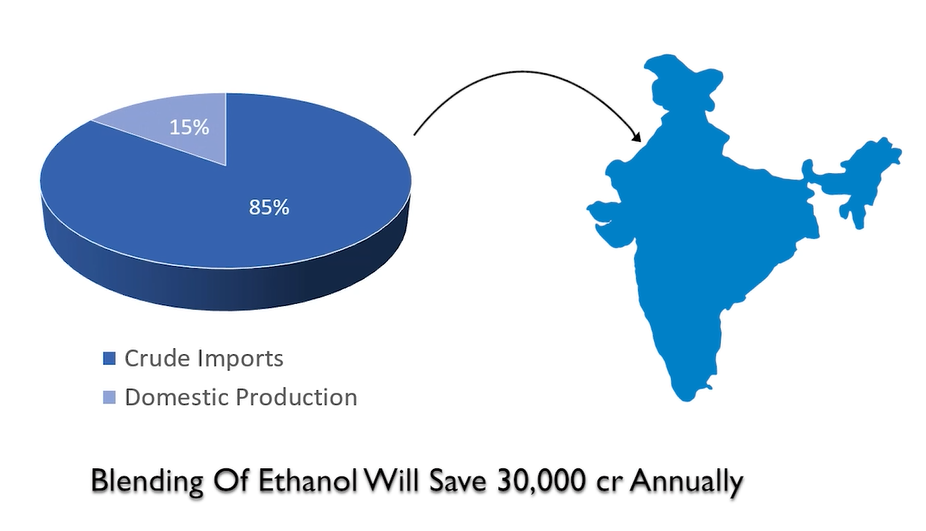

- 85% of crude oil is imported in India which is a big share of government expenditure. This has created a dependency on foreign countries for dometic energy. Blending of ethanol in fuel will save 30,000 Cr annually to the government, thus reducing the expenditure and dependency of domestic energy demands.

- Ethanol will be blended at a certain percentage by the oil manufacturing companies (OMC) to reduce the consumption of gasoline.

- Ethanol has energy density similar to fossil fuel and can be used with a certain percentage blend in the existing IC engines. Also ethanol burns cleaner than other fossil fuels resulting in lower carbon emissions.

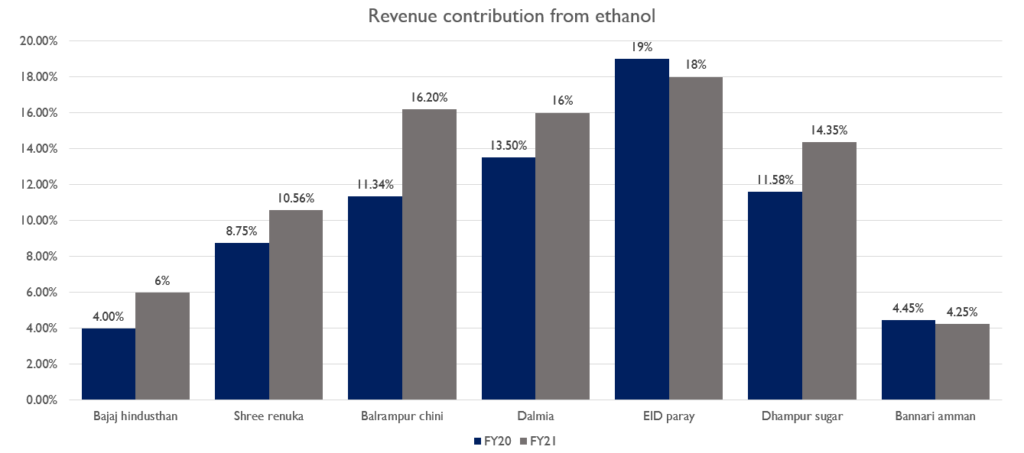

- Sugar companies in India are highly dependent on sugar manufacturing, thus ethanol stands as an alternative source of revenue generation.

What is ethanol?

- Ethanol or ethyl alcohol is the same alcohol used by breweries to manufacture alcoholic beverages, this is known as potable alcohol which has lower concentration and fit for human consumption. The other grades of ethanol are of high purity which are used in sanitizers and as an industrial solvent. High purity grade ethanol is used by OMC’s

- Ethanol is manufactured mainly from sugarcane and foodgrains across the globe, but new technological developments have resulted in efficient processes to procure ethanol from agricultural waste as well.

Global Outlook

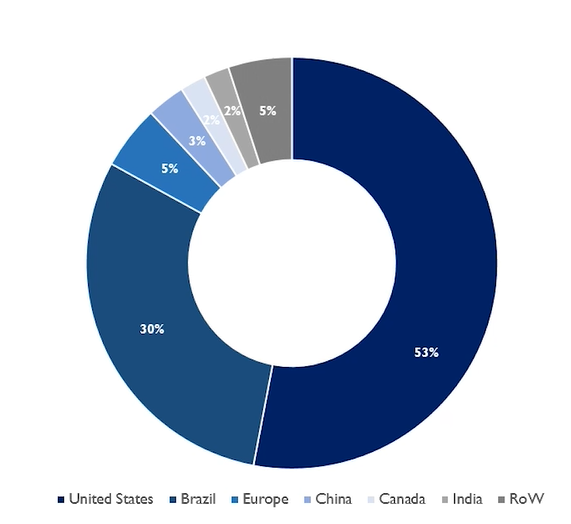

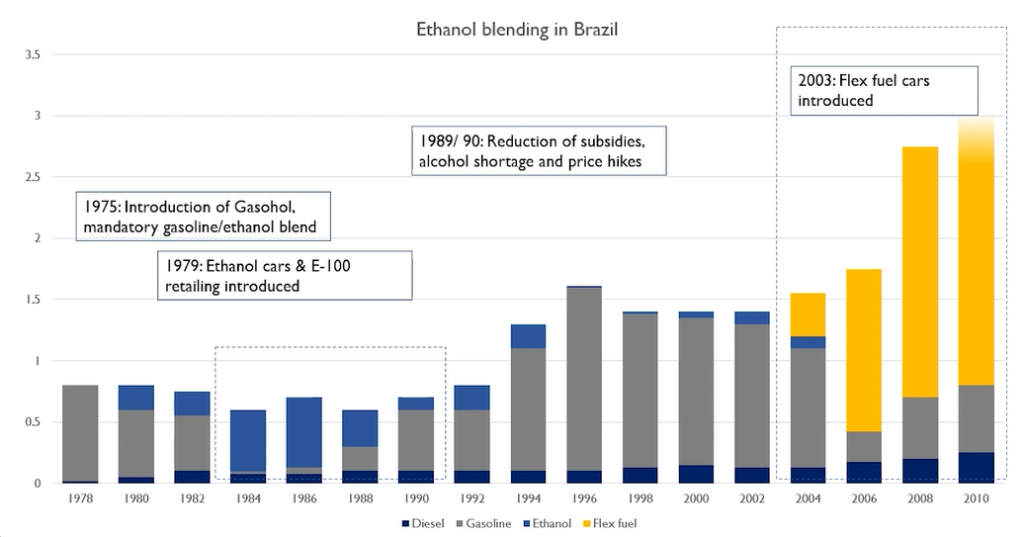

- Ethanol use in fuels was introduced in the 80’s in the USA, but after the discovery of oil in the region and low cost of gasoline manufacturing overlooked the importance of ethanol. Later during the economic crisis, ethanol blended fuel took off due to lower spending by the people on gasoline. Since then the USA is the largest producer of ethanol globally.

- During the oil crisis, Brazil made it a mandate to blend ethanol with gasoline and reduce the government expenditure and dependency on foreign oil. Since then Brazil is the second largest manufacturer of ethanol globally.

Domestic Outlook

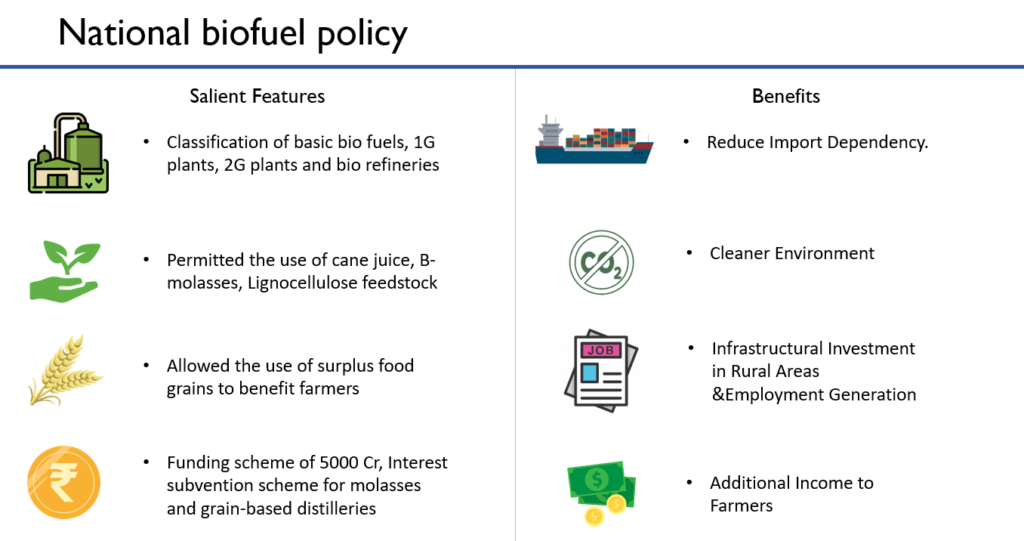

- The Government of India initiated the national biofuel policy in 2018 with the target of increasing the ethanol capacity for blending in fuel. The government has advanced the 20% ethanol blending target to 2025 from the earlier target of 2030.

- Some of the features of national biofuel policy are

- Classification of 1G,2G pants and bio-refinery

- Permitted the use of feedstock such as cane juice, grains and b-molasses

- Interest subvention scheme to sugar companies.

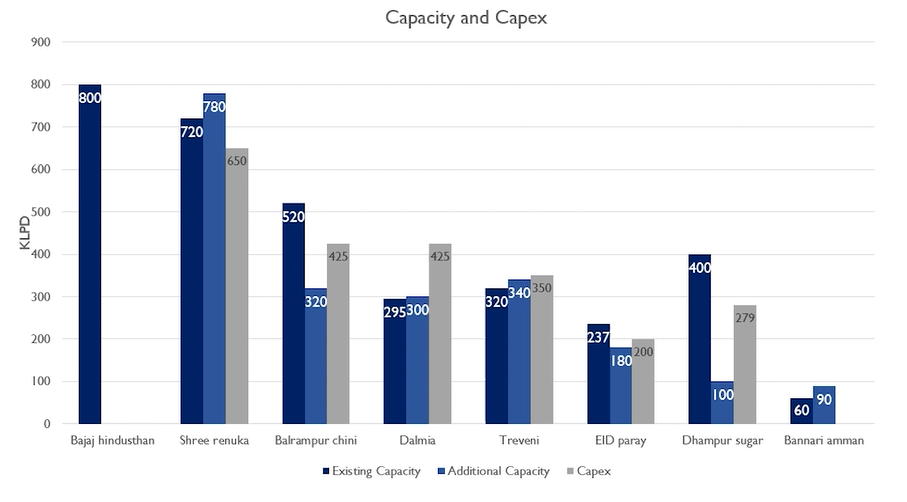

- The government is expecting to double its existing capacity by 2025 to meet the 20% blending targets

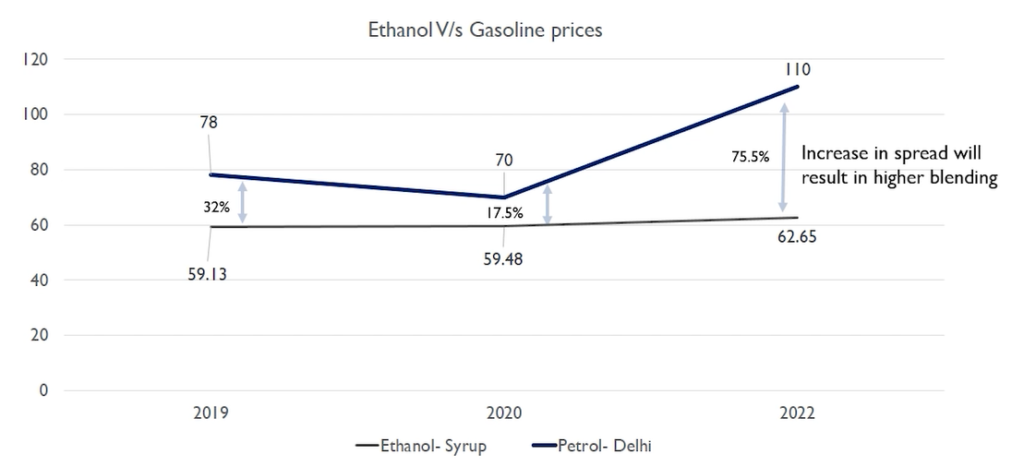

- The higher difference in ethanol and petrol will result in better economics and utilisation of capacity.

Industry Value chain

- Feedstock such as sugarcane, corn, food grains and lignocellulosic raw material is procured from farmers by the sugar/ethanol manufacturing companies. The starch feed is converted to ethanol by fermentation and sent to the oil manufacturing companies who use this to blend the fuel.

Ethanol Manufacturing

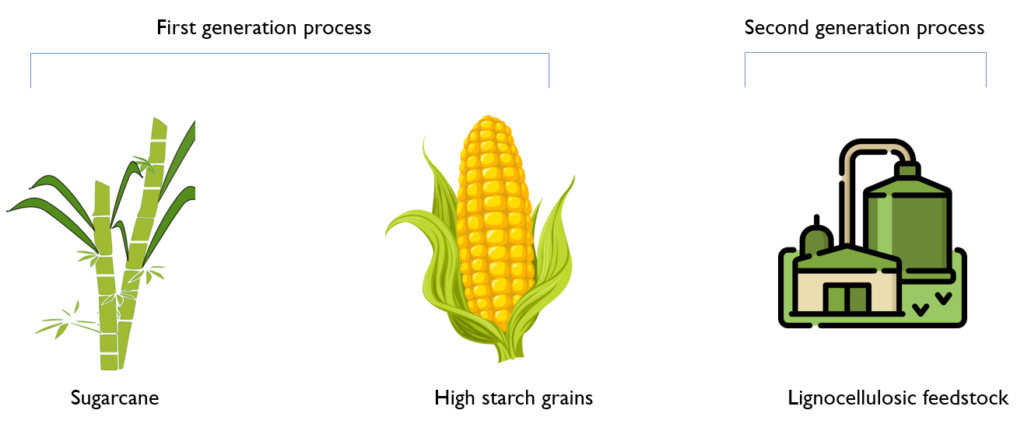

Ethanol is manufactured from 1st generation plants (1G) and 2nd generation plants (2G). The process of ethanol extraction is similar where starch or glucose is fermented to manufacture ethanol, but the feedstock used in both the plants are different.

- Sugarcane and food grains like corn are used as feedstock in 1G pants.

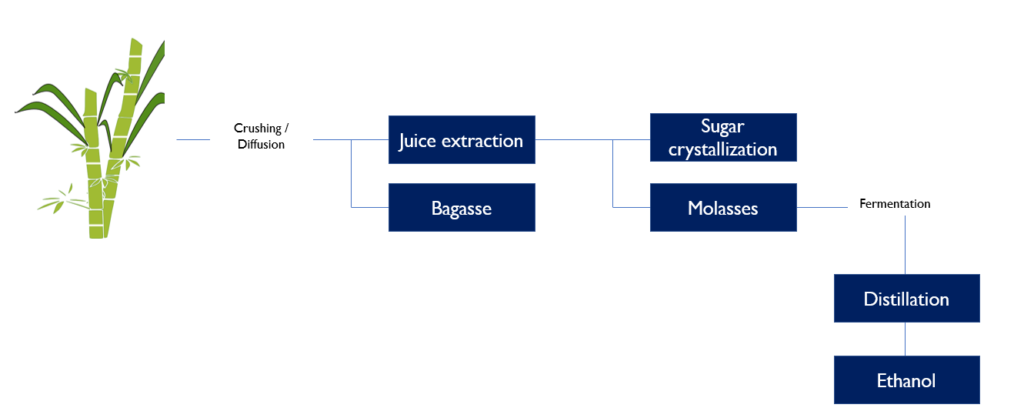

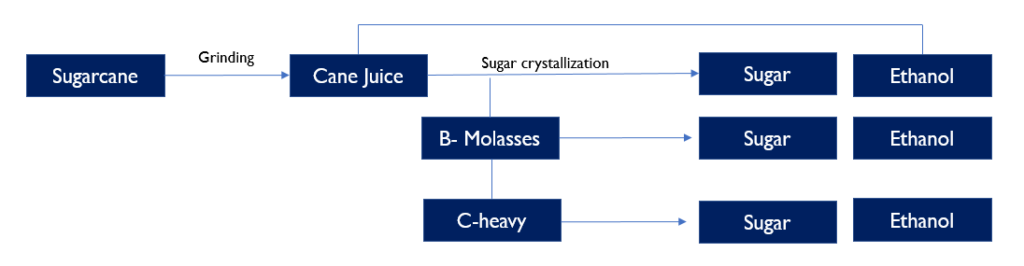

Sugarcane manufacturing: The manufacturing begins with procurement from farmers. The raw material procurement is dependent on the harvest season of sugarcane. Sugar companies extract the cane juice from sugarcane with the byproduct bagasse.

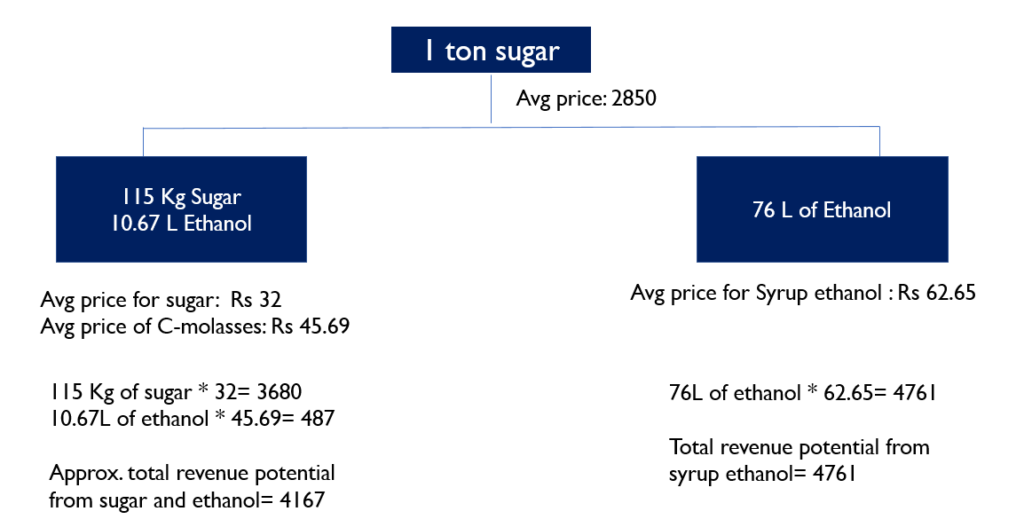

The cane juice is then either used to manufacture ethanol or sugar.

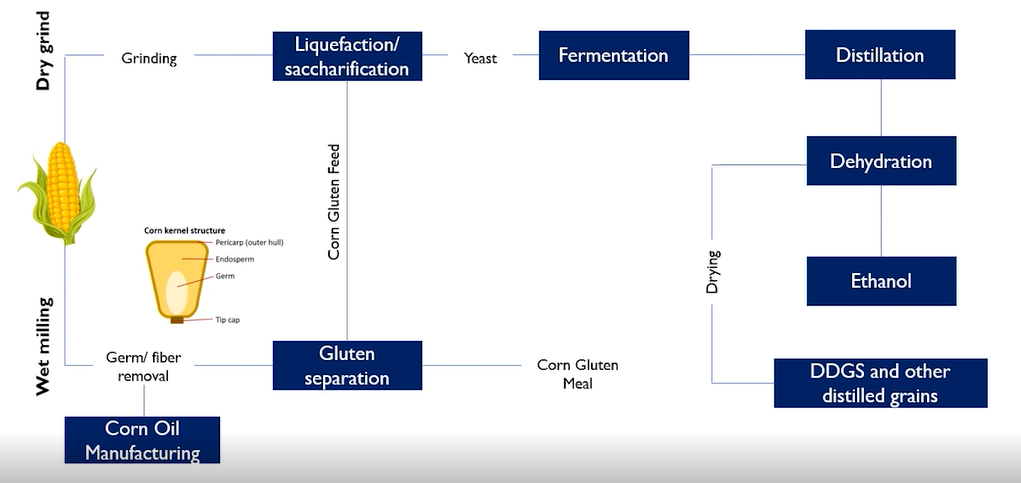

Corn/ grain manufacturing

The corn or other food grains are processed from 2 methods i.e Dry grind process and Wet milling process.

In the dry grind process, the corn procured from fields is crushed into flour and mixed with water to create a mash. This mash is then fermented using yeast or enzymes to manufacture ethanol. However in the wet milling process the germ and the endosperm of corn kernel is separated before being used to manufacture ethanol. The germ is used in manufacturing of corn oil and the rest of starch rich feed stock is sent for ethanol production.

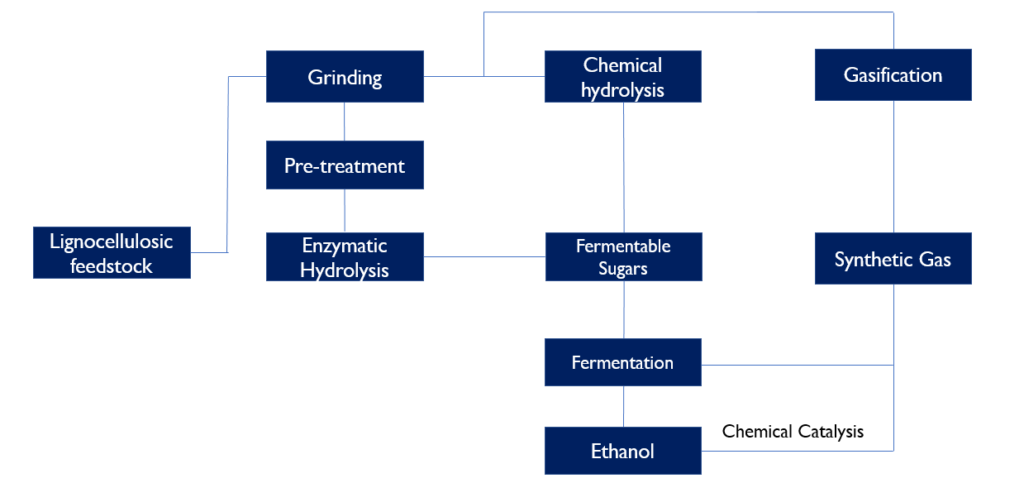

2G plants

Agricultural waste, rice straws, wheat straws and other lignocellulosic feedstock is used as feedstock in 2G plants. Ligocelluosic waste can be waste generated from farms, municipal waste and bagasse from 1G plants etc. Specialty enzymes are added in the fermentation step to accelerate the process and increase the yield of ethanol.

Indian Ethanol Industry

The Indian ethanol industry is undergoing dynamic changes with the new policy, acceptance of different feedstock, increased government spending etc.

BEP (blended ethanol program)

- Ethanol blended fuel is followed by most of the countries to reduce the consumption of gasoline in transportation.

- Increasing the ethanol blends in fuel to 20% which is currently at 8-10%

- Production of E20-tuned engine vehicles from April 2025

- Raise pan-India ethanol production capacity from the current 700 to 1500 Cr litres.

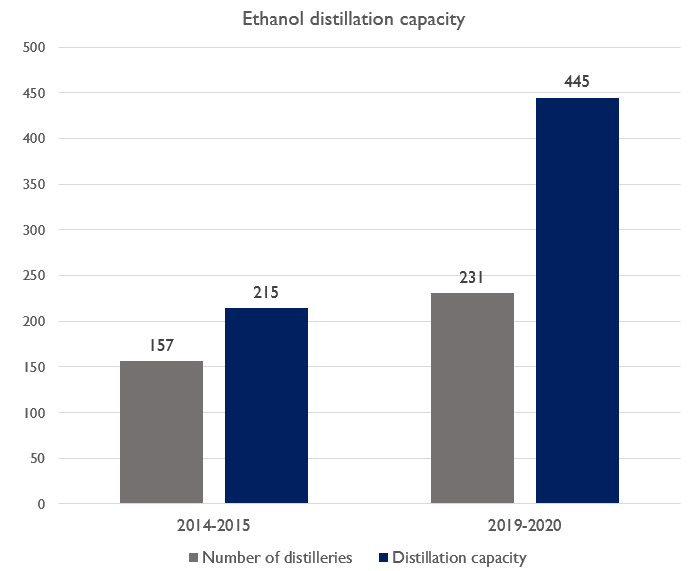

Distillation capacity

- Most of the petroleum products are used in transportation. Hence, a successful E20 program can save the country US $4 billion per annum.

- Ethanol distillation capacity almost doubled in 5 years and storage capacity increased 3X from 2017 to 2020.

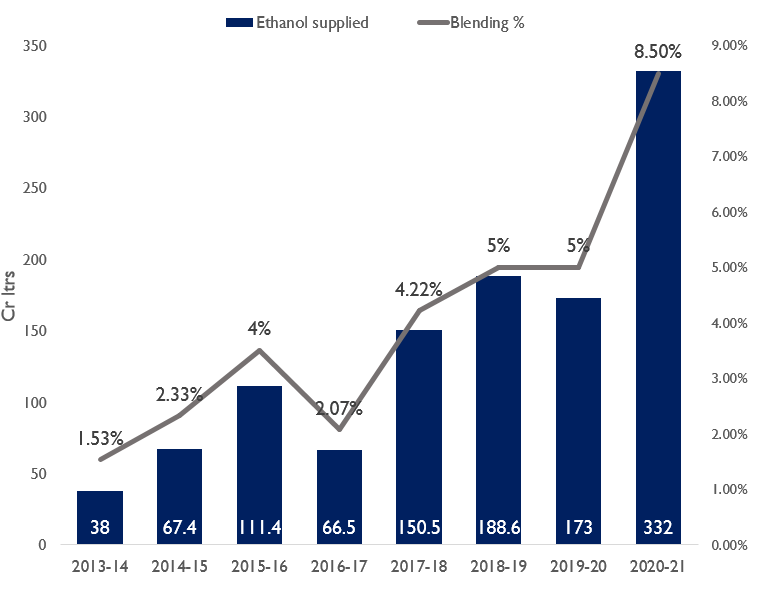

Indian ethanol blending

The ethanol blending in India is currently at 8.5%-10% and is expected to be 20% by 2025. 56% of the total ethanol manufactured in 2019-20 was used for the BEP program.

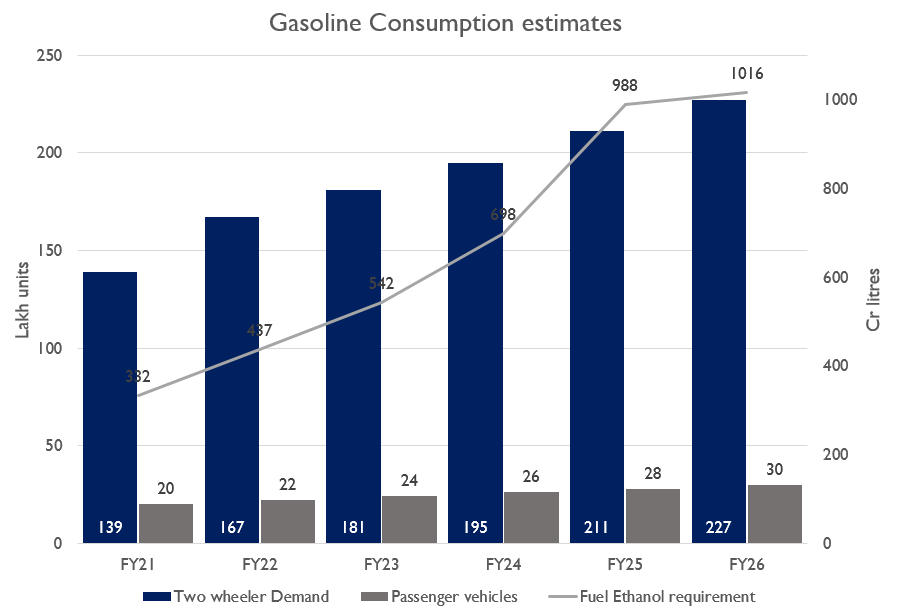

Indian gasoline estimates

Sales of petrol vehicles are expected to be 83% of total passenger vehicles. Emergence of EV will take longer period due to lack of technology and infrastructure.

How is ethanol manufactured in India?

- In India, ethanol is manufactured from sugarcane feed due to abundance of raw material and government restriction on using food grains for energy manufacturing.

- The cane juice is crystalized in the three different steps resulting in sugar as a product and molasses as a byproduct

- After the first boil and sugar extraction, the juice which is left is known as B-molasses. The b-molasses still have sugar content left in it, companies can either manufacture sugar again or manufacture ethanol out of it. If the company manufactures sugar from b-heavy molasses, the juice left after second extraction is known as C-heavy molasses. C-molasses also has sugar content in it, companies can manufacture sugar again from it but it is not economically viable due to high cost, thus c-molasses is used to manufacture ethanol.

Challenges for sugar companies

- The sugar company faces several challenges with procurement, manufacturing and volatility in sugar prices.

- The sugar companies have to pay the farmers within 14 days of procurement or they will be levied with 15% interest making the sugar companies a high working capital business.

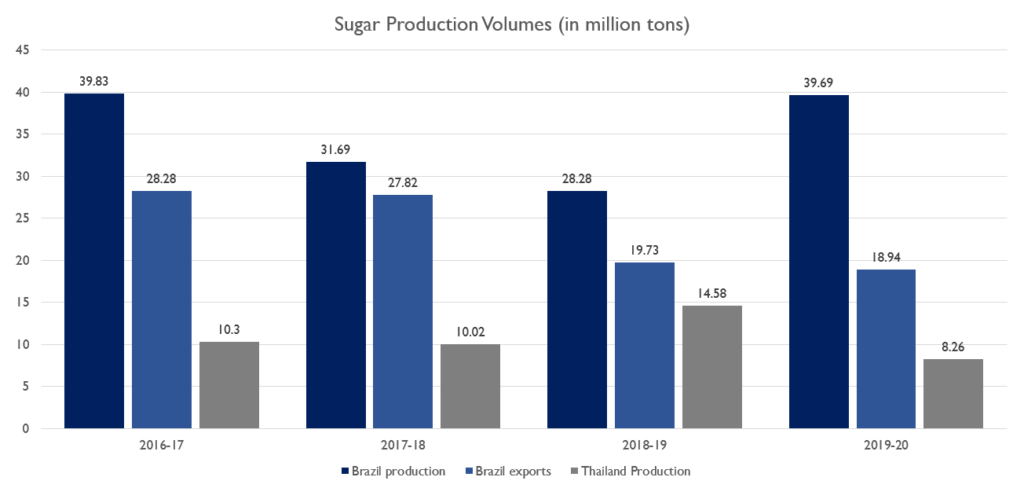

- The sugar companies face price volatility in international markets as Brazil is the largest manufacturer of sugar and annual production numbers impacts the sugar prices. However, the sugar production is expected to be subdued because of drought in Brazil which will result in higher prices for sugar in international markets.

- The government exports subsidy for sugar can no longer be availed by the companies as the government wants to boost the ethanol production and thus reducing the sugar manufacturing due to surplus availability of sugar.

B & C-heavy molasses

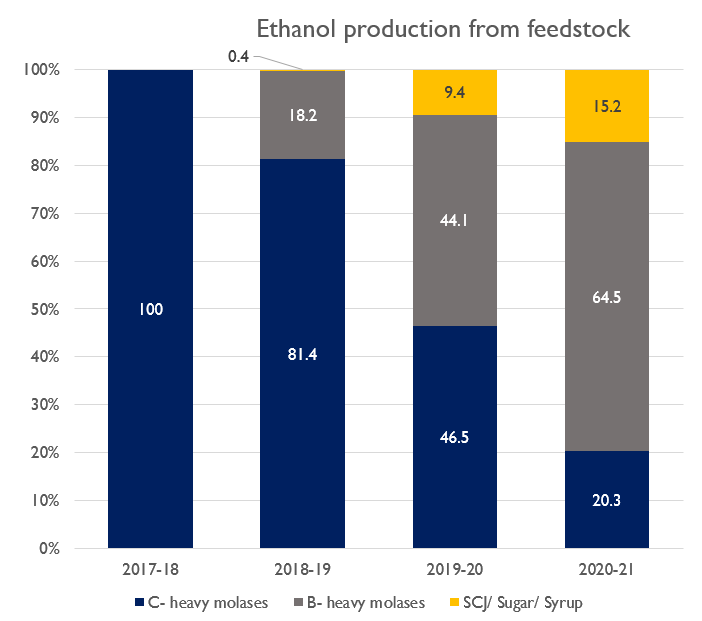

- Before 2018, Ethanol manufacturing was only allowed from C-heavy molasses route due to fear of sugar supply shortage but in 2018 national biofuel policy, the government allowed the use of cane syrup and b-heavy molasses along with grains, and other agri feedstock for the production of ethanol.

- Manufacturing alcohol from cane juice is more economical if sugar prices are lower than ethanol prices.

Economics of ethanol production

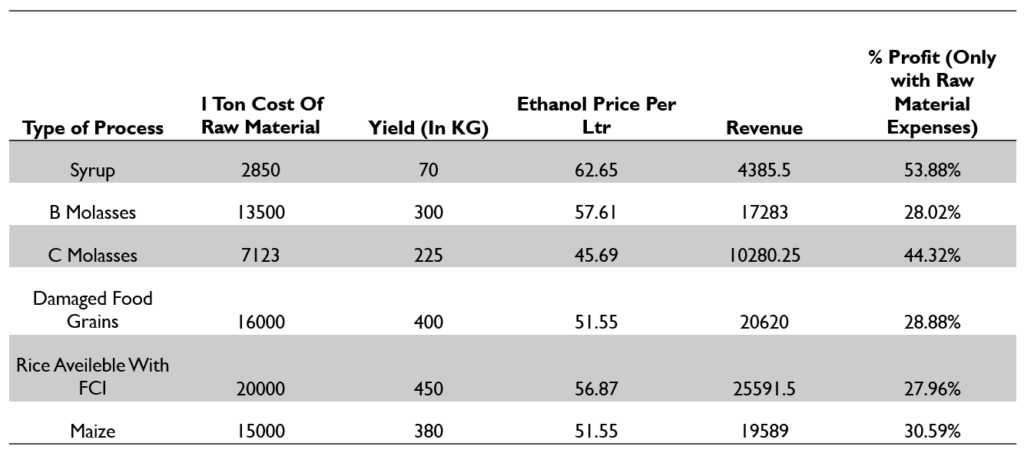

The prices for ethanol changes depending on the raw material used for manufacturing. Cane juice used to manufacture ethanol have higher prices compared to other feedstock.

Ethanol and sugar dynamics

- Manufacturing ethanol directly is more beneficial for sugar companies instead of producing sugar if the ethanol prices stay at elevated levels.

Revenue contribution from ethanol

Upcoming capacities for India

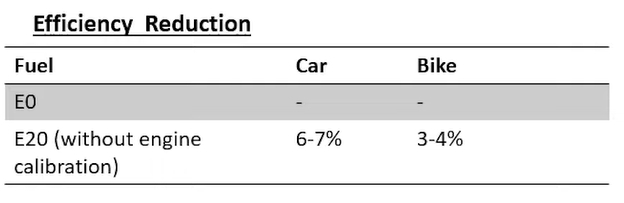

Flex fuel and E100 challenges

- Flex fuel vehicles are different from normal IC engine vehicles as these engines could easily accept and adapt to ethanol blended fuel at any concentration. The flex fuel vehicle engines could digest 95% ethanol blended fuel without engine deterioration

- The government of India is directing the car manufacturing companies to upgrade their engines for adapting higher blends of ethanol fuel.

- Currently manufactured two wheelers and passenger vehicles in the country are designed optimally for E5, with rubber plastic components compatible with E10 fuel.